Decent work on the public agenda in Paraguay

Threading Chains and Weaving Clusters with “Local”: a project to develop territorial capacities in Paraguay’s textile industry

17 de Agosto de 2023

Read the Spanish version here

Among the challenges assumed by Paraguay’s new government are those of generating 500 thousand jobs in the next 5 years and of reforming the country’s pension system, responding to three long standing interrelated issues: high labor informality, the need to increase income and the saving capacity of workers, and the urgency of capitalizing on Paraguay’s the demographic boom of working-age young adults before it becomes a "time bomb" of older adults without adequate retirement savings.

These Paraguayan concerns, shared by many other countries globally and heightened by the effects of the COVID-19 pandemic, are expressed as part of Goal 8 of the Sustainable Development Goals (SDGs), “Promote sustained, inclusive and sustainable economic growth, full and productive employment and decent work for all” and its specific targets of improving economic productivity (Target 8.2), promoting policies for job creation and business growth (Target 8.3) and protecting labor rights (Target 8.8).

Industrialization for Decent Work

Historically, the countries that experienced sustained growth in economic productivity and improved working conditions have been those that transitioned from the production and export of primary commodities to the manufacture and export of finished products (1). For this reason, the Goal of "Decent Work" is closely related to SDG targets 9.2, promoting inclusive industrialization, and 9.3, increasing the access of small enterprises to affordable financial services, value chains, and regional and international markets. However, high levels of international competition and large gaps in technology, investment, and managerial capacity make late-industrialization a formidable challenge.

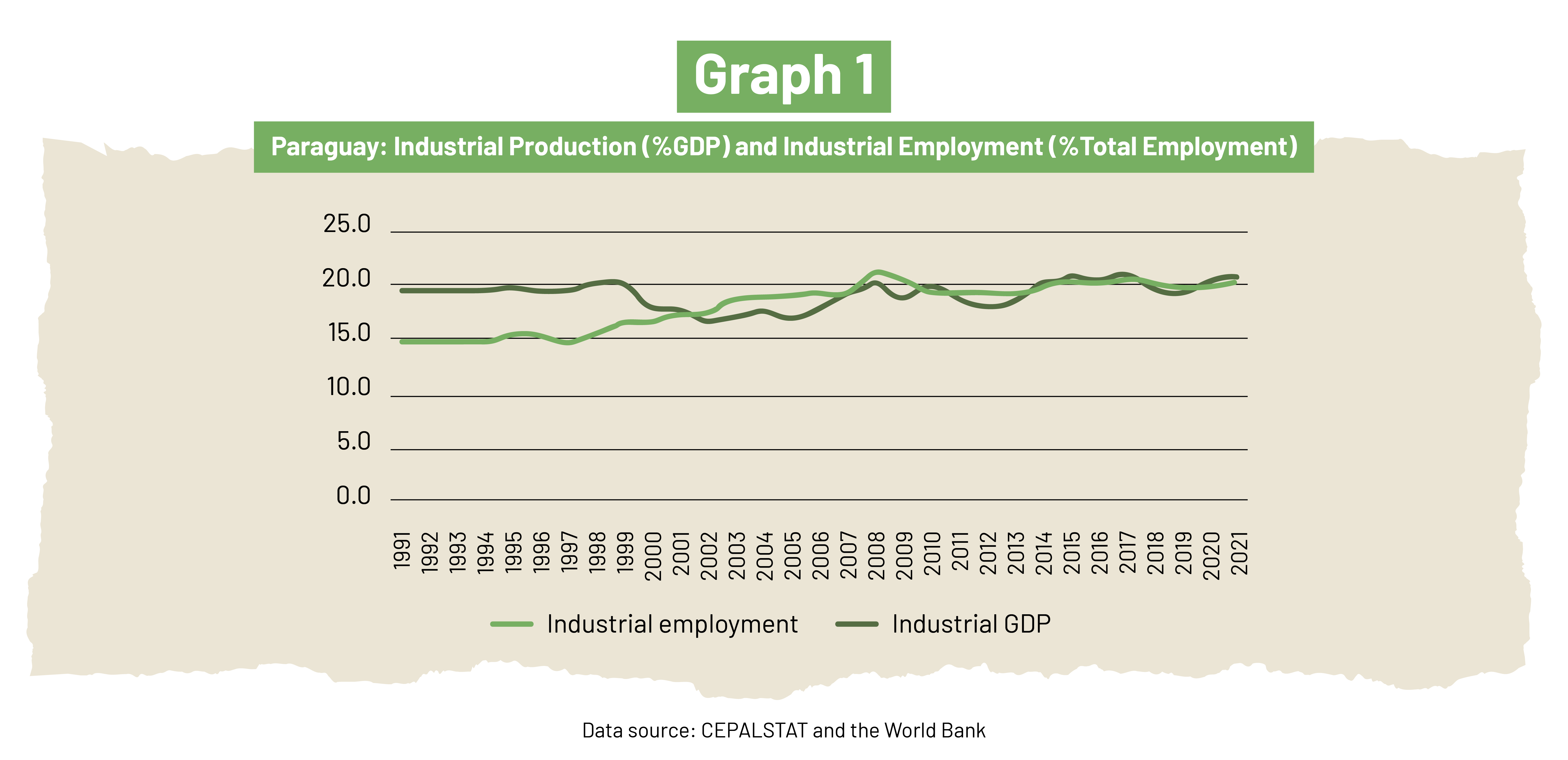

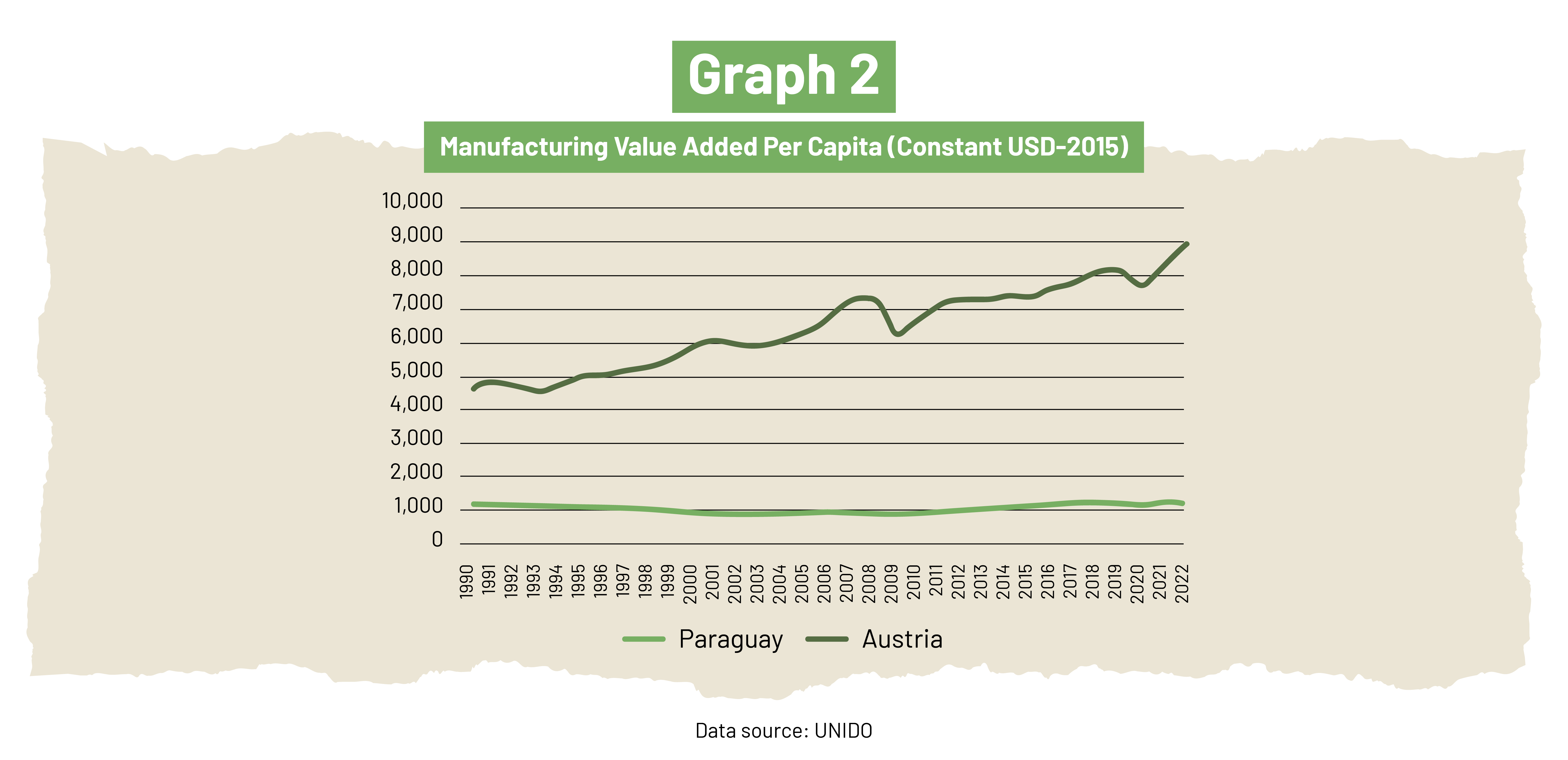

In Paraguay, the share of manufacturing in employment and GDP are substantial and stable, around 20% in both cases (Graph 1). At the same time, the sector's productivity is low: since 1990, manufacturing value added in Paraguay has remained around US$1,000 per person. Since that year, the productivity gap has doubled between Paraguay and Austria–a country where industry also represents 20% of GDP and the population is of a similar size, but which, in 2022, produced 9 times more manufacturing value added per person (Graph 2). This gap, to a large extent, explains and encapsulates the challenges of improving working conditions in Paraguay.

The Potential of Paraguayan Industrial Clusters

Within the Paraguayan industrial sector there is a diversity of clusters made up of Small and Medium Enterprises (SMEs) dedicated to the manufacture of products such as wooden furniture, ceramics, clothing, musical instruments, jewelry, and other products, with the potential to generate economic growth and higher quality employment through flexible manufacturing strategies and collective territorial competitiveness. A central challenge for reaching this potential is to connect local clusters to dynamic markets and help firms and workers adapt to meet quality and other market demands. For SME clusters in the apparel industry, the specific challenges include: (1) improving financial and administrative management, especially in planning and quality control, (2) improving equipment and physical infrastructure, (3) increasing access to and retention of qualified labor, and (4) strengthening and formalizing networks for interfirm collaboration.

Local: Territorial Competencies for Industry Program

The program "Local” led by the UNDP Paraguay Acceleration Laboratory in collaboration with local actors in three territories (Yaguarón, Pilar, Mariano Roque Alonso) aims to develop and evaluate methodologies to respond to the challenges of industrial SMEs, starting with the apparel industry. The project’s concrete steps include: A census of apparel workshops in three territories; The selection of 5 workshops in each of the territories, in addition to lead firms; A diagnosis of capabilities and weaknesses in the areas of infrastructure and machinery, product quality management, organization and methods, productive specialization and added value, human resource management, work conditions and safety, administrative and financial management, and associationalism. The preparation of an improvement plan for each participating apparel workshop in collaboration with lead firms. The plans will state specific goals and actions in these areas, and the workshops will receive technical assistance for their implementation. The evaluation of the results and lessons learned from the project for the design and implementation of industrial policies in Paraguay.

The type of productive upgrading refers to the different dimensions of improvement in industrial productivity, including process improvements through the incorporation of new production technologies, techniques and practices; product upgrading, through quality improvements or the production of new higher-value products: and functional upgrading, to integrate new value-added processes or services that come before or after manufacturing operations in the value chain. With social improvements we refer especially to working conditions such as the payment of a decent wage, access to social security, and the safety and hygiene of work environments (2).

Among the most relevant elements of territorial context for promoting industrial upgrading are the accumulation of manufacturing experience and productive specialization; the existence trade organizations or associations and their capacity to articulate collective action for local development; the agglomeration and availability of a qualified workforce; and local public investment in infrastructure, production and business training, and research and development (3).

Finally, the degree of local involvement and the level of dynamism of lead firms as articulators of market information, national and international market demand, production and technological knowledge, and finance are key variables to understand the rate of productive upgrading in industrial clusters and the types of improvements that are more or less feasible (4).

The three selected territories provide different scenarios to analyze industrial upgrading in the Paraguayan apparel industry.

In Pilar, a long-standing lead firm, Manufactura Pilar, maintains productive and commercial relationships with about 25 small and medium-sized workshops to produce pants, shirts, and kitchen- and bedware. Dwindling access to raw materials and the ups and downs of the export market profoundly mark the pace of development of Manufactura Pilar’s supply chain and, more broadly, of the 154 workshops and seamstresses identified in the census of local clothing manufacturers. A pre-cooperative is in its initial phases of organizing these workshops to seek new markets and provide more secure working conditions for a workforce that is exiting the sector due to its precariousness. The local government is just beginning its attempts to articulate policies for the sector.

In Yaguarón, one of the most prominent manufacturing centers in the country, several lead firms source from almost 160 small and medium workshops and a few large factories that produce a variety of products including pants, T-shirts, shirts, work and school uniforms, sportswear, and other products for the local, national, and export markets. On the other hand, Yaguarón’s workshops produce a significant volume of jeans for Paraguay's local markets, generally in informal conditions. A local association of apparel workshops has managed to articulate credit and commercial support for its members but, as in many sectors in Paraguay, it must overcome the mistrust produced by high social and economic inequalities in the community, the scarcity of opportunities, and the legacy of failed projects. As in Pilar, the local government is just beginning to consider policies to support the industry.

Finally, in Mariano Roque Alonso, the 56 workshops registered in the census are mostly small (with less than three operators) and independent–producing products for the local market of the Asunción Metropolitan Area. In general, they do not have stable relationships with national or international lead firms, and they do not yet have an association. However, the municipal government promotes contacts with local entrepreneurs through its office for neighborhood committees, and it is project headquarters “Ñasê Tenonde Gotyo”, which seeks to articulate municipal management in 11 districts for sustainable development, including industry.

Local, as an agile “learning loop,” began with the census of workshops in Yaguarón in August 2022 and will run until December 2023. It seeks to generate lessons on how to overcome the challenges for business coordination and collaboration at the territorial level and how to development demand-driven interventions for improving productivity and working conditions to complement existing development projects focussed on SMEs in Paraguay, such as MiPYME COMPITES, FOMIPYMES, and REEMUJERPY.

In future blog posts we will present more details on the apparel workshops’ challenges, the lead firms that participate in Local, and the lessons we learn along the way.

1. UNCTAD (2014). The Least Development Countries Report 2014. Growth with Structural Transformation: A Post-2015 Development Agenda. United Nations publication. Sales No. E.14.II.D.7. New York and Geneva. https://unctad.org/en/PublicationsLibrary/ldc2014_en.pdf.

2. Barrientos, S., Gereffi, G., & Rossi, A. (2011). Economic and social upgrading in global production networks: A new paradigm for a changing world. International Labour Review, 150(3‐4), 319-340.

3. Schmitz, H. (2000). Does local co-operation matter? Evidence from industrial clusters in South Asia and Latin America. Oxford development studies, 28(3), 323-336.

4. Gereffi, G., Humphrey, J., & Sturgeon, T. (2005). The governance of global value chains. Review of international political economy, 12(1), 78-104.

Locations

Locations