By Jean-Paul Mvogo, Head of Experimentation | UNDP Cameroon Accelerator Lab

Will drone and artificial intelligence help increase the income of Cameroonian cocoa planters ?

May 14, 2021

UNDP Cameroon Accelerator Lab recently launched experiments aimed at finding innovative solutions for cocoa planters. This decision is rooted in a paradox. The sector is of systemic importance, as it represents the second source of export revenues for the country, after oil. Yet, cocoa planters hardly receive the recognition they deserve by the media and many Cameroonians who tend to focus on more glamorous occupations, ignoring thus the difficulties in that sector. As a reminder, 257 151 tons were collected for the 2019-2020 campaign, -2% in comparison to the previous period, and cocoa tonnage produced has been decreasing since 2016.

A drone used for experimental purpose by the UNDP Cameroon Accelerator Lab hovers in a cocoa field plantation. | Credit: Rodrigue Martial Mbarge et Severin Ndemanou

Meeting Mr. Fouda: A long and rich journey that became our 101’s guide to the Cameroonian cocoa value chain

Our second meeting with Mr. Fouda, a cocoa planter, took place in that context as the Accelerator Lab team tried to better understand the issues plaguing the Cameroonian cocoa value chain. Far away from our office in Yaounde, the capital of Cameroon, the meeting took place in Tambe - a typical village, located in one of the Cameroonian cocoa belts - where he owned a 4 hectares cocoa field planted with young trees.

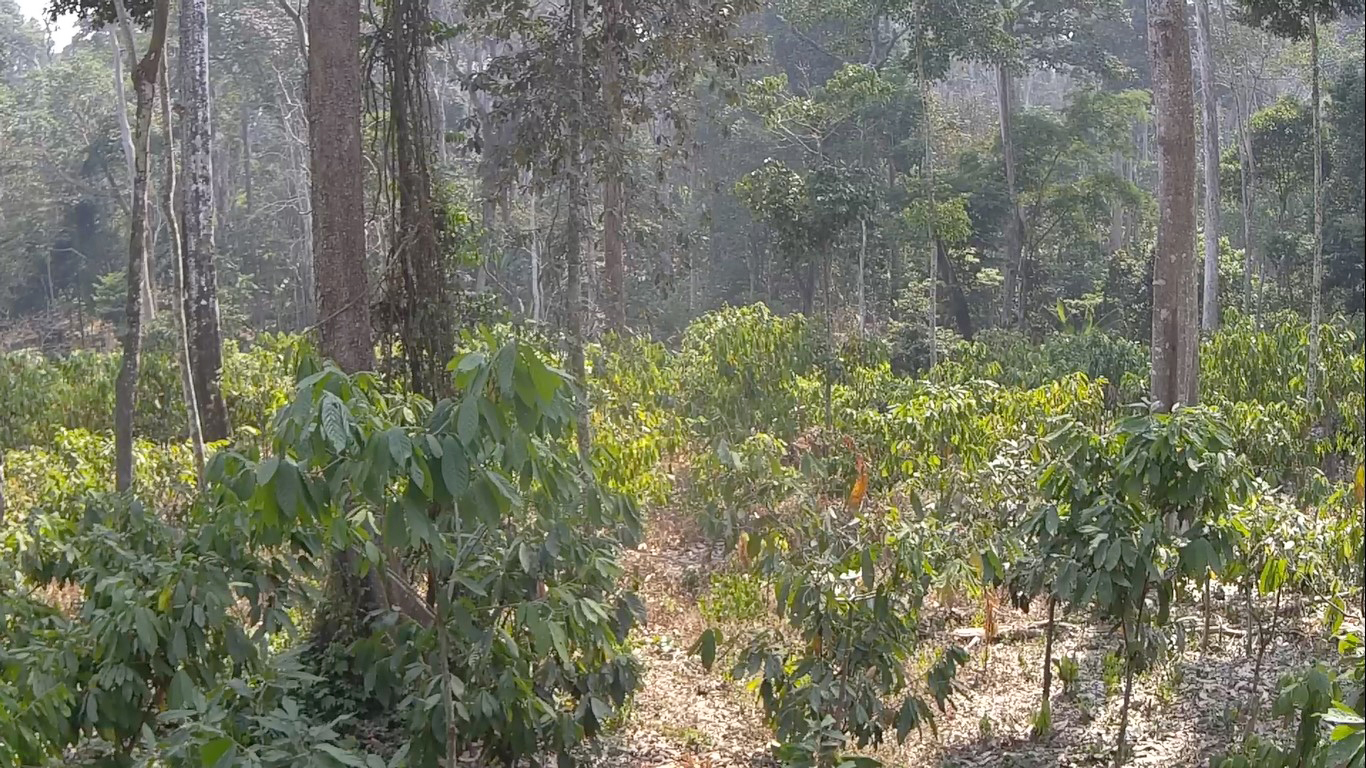

This encounter confirmed my opinion on cocoa planters. They resembled in many respects those characters portrayed by Hemingway or Zola and who are full of exceptional energy, calm and determination. Like those characters, Cameroonian cocoa planters wage a daily struggle against an indomitable force, here the rainforest, as a large part of cocoa harvested in Cameroon is planted under trees, deep under the canopy.

This mode of exploitation requires a constant commitment from planters. On a daily basis, they have to cover long distances on foot to monitor the growth of their cocoa trees. This activity which is imperious to prevent the spread of diseases that can ruin months of labor in a few days. And because meccanization is only a faraway dream, all works have to be done with machetes. And this from the maintenance of the tiny paths linking main roads to fields located deep in the forest to the logging of trees to provide light for the young cocoa trees.

According to Google Map the journey to meet Mr. Fouda and his fellow cocoa planters was supposed to last 3 hours and 37 minutes. In real life conditions, it took the UNDP Cameroun Accelerator Lab Team more than eight hours to travel the 161 kilometers between Yaounde, the capital of Cameroon, and Tambe. For us, this journey was synonymous of dusty roads, hardly practicable, wooden bridges and a foretaste of the various logistical post-harvest constraint faced by planters as they have to transport cocoa bags from their fields to commercial hubs. It was also an opportunity to deploy the know-how of the Accelerator Lab. Audrey Moneyang, our Head of Exploration was able to discuss with planters about their constraints. Anna Ojong, our Head of Solution Mapping did collect local answers used by planters to solve their challenges. Finally, as the Head of Experimentation, this journey, which may have lasted several days during the rainy season, was an opportunity to test and start validating several innovations.

UNDP Cameroon Accelerator Lab mission discover a foretaste of the cocoa planters’ logistical conundrum. Location: Near Mbangassina, Centre Province of Cameroon | Credit: Jean-Paul Mvogo

In fact, our mission to Tambe had started a few days ago as we were incidentally introduced to Mr. Fouda, by the Head of the TRIDOM II project, a UNDP Cameroon unit working to maintain biodiversity in the Congo Basin. The encounter was rooted in our first frontier challenge aimed at improving the access of young people to entrepreneurship and employment. Early sensing activities concluded that young people in rural areas were often the poor relative of Youth policies. Though, they account for 42 % of that age group, young rural people have access to fewer technological and job opportunities, with more than 70% of people living in rural areas occupied in agriculture, according to ILO.

Arrival of the Accelerator Lab Team in Tambe and first meeting with representatives of the area chief. Location: Ngoro townhall, Centre Province of Cameroon | Credit: Rodrigue Martial Mbarge et Severin Ndemanou

.

Progression in cocoa fields located under the rainforest canopy, with Mr. Fouda, a planter and our guide into the subtleties of the cocoa value chain, leading the group. Location: Near Tambe, Centre Province of Cameroon |Credit: Rodrigue Martial Mbarge et Severin Ndemanou

As we analyzed those realities, we decided to give more attention to young people living in rural areas. Systemic thinking exercise led us to understand that actions aimed at improving the functioning of agricultural ecosystems may have decisive impact on their living. And cocoa production immediately emerged as a game changer for many reasons. First, it is estimated that 1 out of 4 Cameroonians live directly or indirectly from cocoa value chain. Secondly, the sector is said to employ more than 600 000 people. Finally, that crop is cultivated in 7 of 10 regions of the countries.

An initial analysis of the potential leverage points for the Accelerator Lab focused on the constraints undermining the daily routine of young farmers. As we discussed with them, they pointed poor access to inputs and seeds as the first bottleneck upstream in the value chain. Then, insects and diseases that constantly threaten the health of the cocoa tree, leaves and pods were identified as a major issue. Logistical issues also undermine their efforts as illustrated by post-harvest costs estimated for each ton.

Innovators and Accelerator Lab Team discuss cocoa production issues with planters in Tambe, Centre province of Cameroon. Location: Tambe, Centre Province of Cameroon | Credit: Rodrigue Martial Mbarge et Severin Ndemanou

Innovators and Accelerator Lab Team discuss cocoa production issues with planters in Tambe, Centre province of Cameroon. Location: Tambe, Centre Province of Cameroon | Credit: Rodrigue Martial Mbarge et Severin Ndemanou

Those issues arise right after the collecting of cocoa pods as planters must first rent moto taxis, called “benskins”, to help them carry bags one by one from deep inside the forest to villages, before having to wait for trucks. Mistrust represents another issue as it undermines the functioning of farmer’s groups. Thus, planters must often yield to the purchasing power of “coxeurs”, as they fail to present a common stance in terms of selling price and conditions.

Beyond those pre and post-harvest root causes, planters are not engaged in transformation and sell their product raw, after drying and sorting. All in all, those factors explain that planters only reap on average 6 % of the price of a chocolate bar, according to Fairtrade, whereas they account for the most labor-intensive part of the value chain.

An overview of logistical operations in the cocoa value chain. Right: Mr. Fouda after the harvest. Centre: Unloading of a bag of cocoa carried by a motorbike, or benskin, safter the harvest. Left: Drying of cocoa. Location: Tambe, Centre Province of Cameroon | Credit: Rodrigue Martial Mbarge et Severin Ndemanou and Edmond Fouda

Considering the above root causes undermining planter’s value creation, a strengths/weaknesses analysis pointed that it would be difficult in a limited time lapse to address the road and logistical constraints. Alternatively, a series of factors led to focus the AccLab first intervention on improving the management of diseases by planters. According to planters, diseases and insects decrease potential production by up to 30 % of losses. Long distance and steep terrain make it difficult to monitor diseases in plantations. Young planters also expressed their difficulties to identify the illnesses and insects affecting cocoa trees as they often received limited training on that topic, in the realm of state-sponsored programs to revive the cocoa sector. Finally, planters suffer from poor intergenerational knowledge transmission on diseases, leading to above average losses for young planters, poverty, and rural exodus. And because of some of those issues, treatments are not often adapted to the disease or poorly executed.

The strategy to provide solutions to Mr. Fouda and his colleagues included the preparation of several experiments aimed at improving disease management by farmers. They are ongoing and include technological, institutional and socio-cultural innovations. An example of innovation that we would like to test is the introduction in the community of discussion groups on cocoa diseases. In the realm of that grassroot cheap solution, planters may collect samples of leaves or cocoa pods affected by a disease or insect and organize thematic discussions.

Harnessing drone and Artificial Intelligence to better monitor the myriad of diseases affecting cocoa production

Beyond that example, we used our field trip to Tambe to test some more technological innovations. In particular, we team up a Cameroonian innovator, William Elong, who has been working on drone imagery solutions with a young developer, Giovanni Gweth, specialized in artificial intelligence. Both have quite a record in their respective fields of expertise. The final objective of that association was to develop and test a solution able to use drone imagery to obtain nearly real time detection and monitoring of diseases across large spaces, for cocoa trees located under the canopy.

Right: Discussion between the technical team before the launch of the drone. Left: drone operations and its interest are presented to Mr. Fouda, a cocoa planter. Location: near Tambe, Centre Province of Cameroon | Credit: Rodrigue Martial Mbarge et Severin Ndemanou

Ease, coverage, speed and accuracy of disease monitoring were some of the selection criteria that fueled the launch of that experiment. A more precise identification of diseases thanks to a broader database pleads in favor of that solution. From discussions with our innovators emerged the perspective of an easier and quicker monitoring of disease. Currently, this process is time-consuming and exhausting. Mr. Fouda estimated at two to three days the time necessary to perform a quick and inaccurate scan of diseases on his 4 hectares. Meanwhile, several trees can be infected by a disease, such as the swollen shoot, a virus that has been decimating cocoa plantation all over Africa.

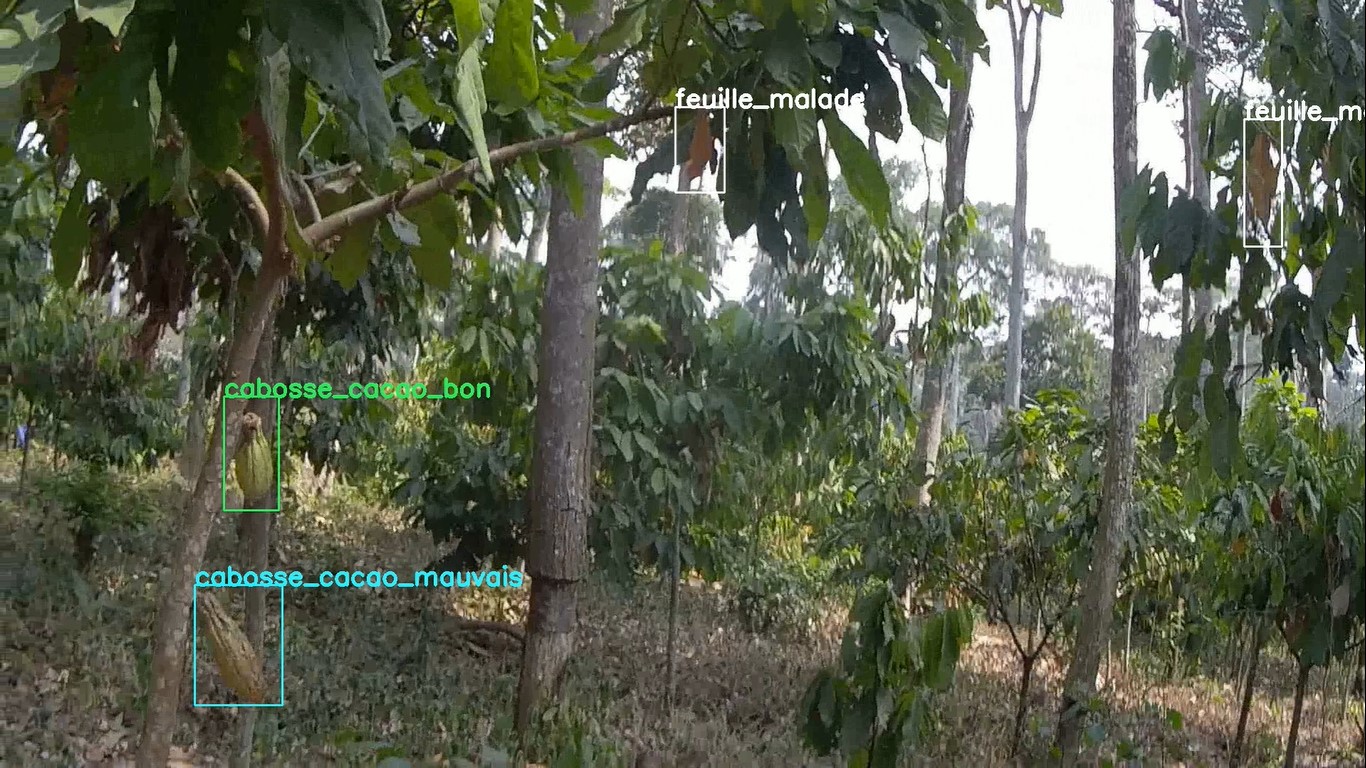

Beyond the Lab Team, we brought a drone operator in Tambe. Drone detection of diseases is not new in Cameroon as that technology has been used for pineapple fields owned by large corporations. Yet, this trip was a good opportunity for him to discover the limits of drone operations under the rainforest canopy. The artificial intelligence engine’s developer was also able to better calibrate his “supervised deep learning” model thanks to discussions with planters and pictures taken by the drone. “Deep learning” models applied to imagery involves creating digital neurons that can replicate the workings of the brain to detect objects and features in pictures. The neural network thus created is trained, like the brain, to recognize objects and their characteristics (in our case diseased leaves and pods). In our case, much like a child's first steps, artificial intelligence network training is accomplished by submitting images of both good and bad leaves or pods to the neural network. Like the human brain, the artificial intelligence model will be able to subsequently detect diseased leaves and pods on new images provided by the drone.

All in all, preliminary results from that field missions are promising. Drone flights went well but we discover that we should privilege some types of drone equipment as their radio signals are less jammed by giant trees. Drones were also able to maneuver below the canopy quite easily, despite the challenge. More importantly, it was estimated that a drone can cover more than 20 hectares per hour in that environment, more than what a planter can in 24 days, if we consider the monitoring rate given by Mr. Fouda. Early results from the artificial intelligence engine are also good as highlighted in this video. It detected cocoa pods and leaves affected by disease or insects as highlighted in this video, with an accuracy rate of 80% so far. That rate will increase as the deep learning neurons are enriched with more pictures and cases of diseases.

The Accelerator Lab Team is currently planning a second mission in Tambe in July to experiment other solutions and deepen results for the Artificial Intelligence/Drone combination. Technically, the mission will aim at testing medium and long-range detection but also operations during the rainy season. Geolocation of sick cocoa trees and fully automatic are also on the table to address the challenge of the rainforest environment. Finally, it would also be an opportunity to train planters to the solution, validate various User Experiences and to answer questions on their capacity to master and adopt such a technological innovation, given the limited exposure of planters in rural areas to digital solution.

Disease detection performed by the artificial intelligence solution on pictures taken in the field of Mr. Fouda. Location: near Tambe, Centre Province of Cameroon | Credit: Jean Ango et Giovani Gweth

Since our return from Tambe, as an Experimenter, I have been questioning and challenging solutions aimed at fighting against cocoa diseases, with an assessment of each solutions pros and cons. This exercise matters all the more for UNDP and the AccLab in a context characterized by scarce resources and a demand for cost effectiveness. Before other stakeholders express that concern, a preemptive brainstorming exercise around the relevance of the drone and AI solution was therefore run. Several questions emerged, especially around Tech solutions. Is a more frugal solution more suitable, such as discussion groups? Aren’t we succumbing to techno-centrism, trying to solve problems with only complex technological innovations? Can this tech solution be easily operated by planters or other stakeholders? Can they afford the costs of the solution?

On those questions, discussions with innovators and planters led to a humble conclusion and some reflections for future operations. As far as the humble conclusion is concerned, I believe that answering Tambe’s planter problems definitely requires a holistic approach, with interventions all along the value chain so that they may earn more than those 6 % on a chocolate bar they currently get.

For the thoughts on future systemic support to those planters, the Accelerator Lab Team has started exploring other solutions such as started building partnerships capable of improving the capacity of planters to achieve such a goal. For example, within UNDP Cameroon, horizontal synergies are sought with other UNDP Cameroon programs, such as the Presidential Program for Reconstruction and Development (PPRD). Among many activities, this program envisions to revive cocoa value chains in areas affected by political unrest in the North West and South West of Cameroon. The AccLab intends to scale and transfer the knowledge acquired to the terroirs and planters in North West and South West Cameroon. Exploratory contacts have also been made with a world class cocoa broker to consider the development of some of our experiments in the realm of its CSR programs.

This drone and AI solution does not have the pretention to be a panacea. Yet, reasons to support such a technological solution are twofold. First, early round of calculations and benchmark with other Agritech solutions have shown that the drone/AI model to detect diseases could be viable, under some cost sharing assumptions among farmers. As the Device as a Service (DaaS) model has gained traction Cameroon, with planters discovering the cost and benefits of renting agricultural tools, adoption might be easier. The Accelerator Lab has started providing support to innovators so that they may turn their technological success into a deployable and successful solutions. Our next deployment to Tambe will therefore be used to validate operational and financial assumptions but also the User Experience (UX) of the solution with farmers.

Strategic reasons are also underlying our motivation. They are linked to the evolution of the technological content of the cocoa value chain in the upcoming years. World largest cocoa traders have been investing in R&D programs focused on the digitization of the value chain, especially in realms such as E-Supply chain, Market forecasting, Field Operations Management but also Financing. In this regard, those investments will shift even more the balance of power within the value chain. Hence, the need for UNDP and its partners to prepare Cameroon and its planters to that revolution. Notably, by supporting local players capable of distributing fairly such a technological revolution at the grassroot level. Those local actors will enable planters to better reap the benefits of their work by equipping planters with the right innovations. As cocoa remains a strategic sector for Cameroon and many African countries, our support also intends to build local and pan African champions, mastering technologies that will be so critical for the future of the sector.

By doing so, we therefore ambition to help Cameroonian cocoa planters reap more than the 6 % they currently get on each chocolate bar.

Group picture with cocoa planters in Tambe. Location: in Tambe, Centre Province of Cameroon | Credit: Rodrigue Martial Mbarge & Severin Ndemanou

Special thanks to the inhabitants of Tambe and Mbangassina, in the Centre region of Cameroon, who welcomed us and shared their knowledge with us. We are also grateful to our wonderful UNDP driver Manel Ango, who drove us through that journey from Yaounde, Hermann Aurelien Kamougne Ndjampa of UNDP, for the layout and to Euphrasie Kouame, Gilbert Ndzomo Abanda and Yannick Elouga for their pieces of advice.

Locations

Locations