A young Ghanaian who benefited from UNDP’s youth innovation challenge is boosting guinea fowl production in Northern Ghana with egg incubators he made from scrap fridges and other materials.

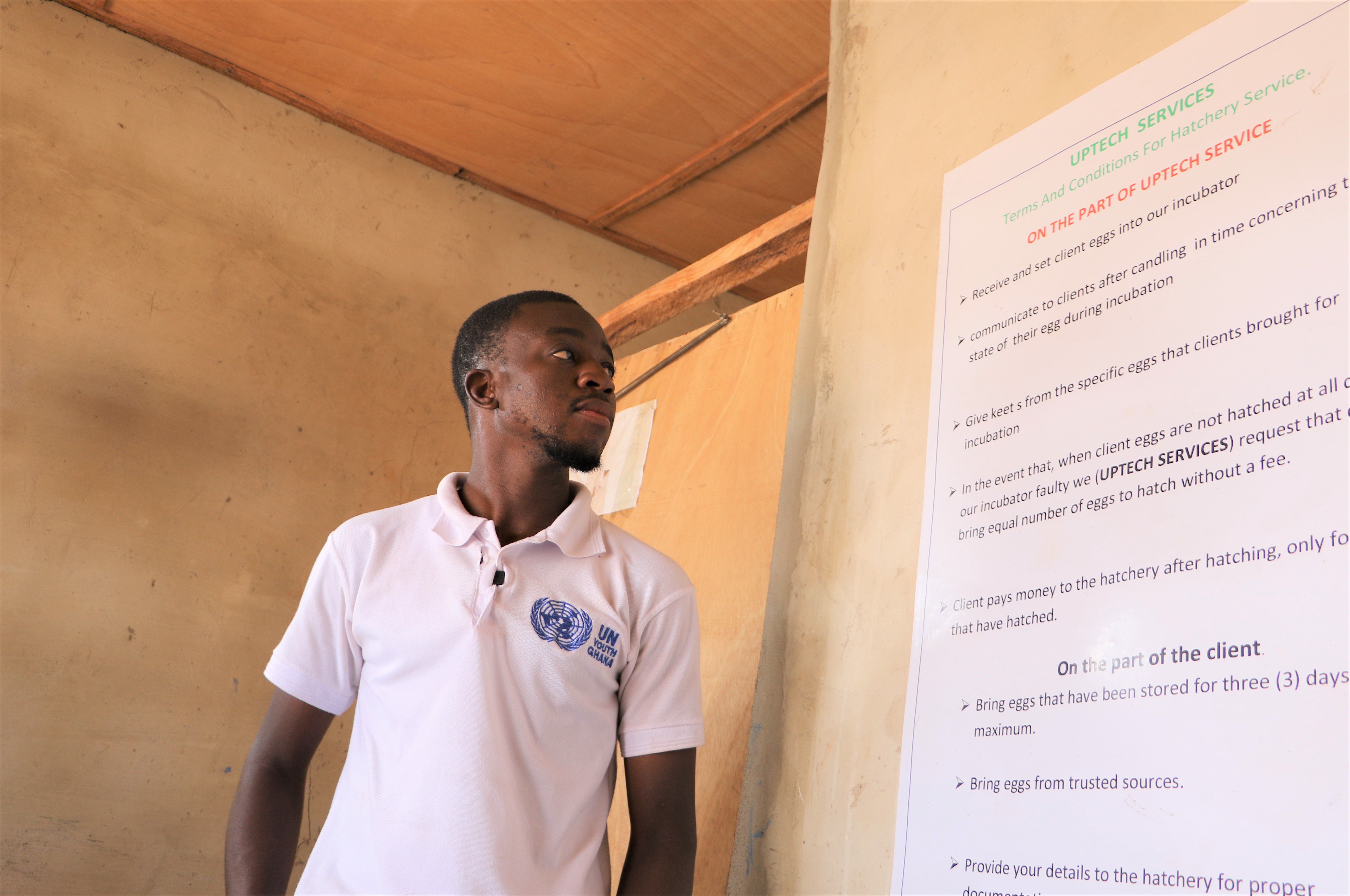

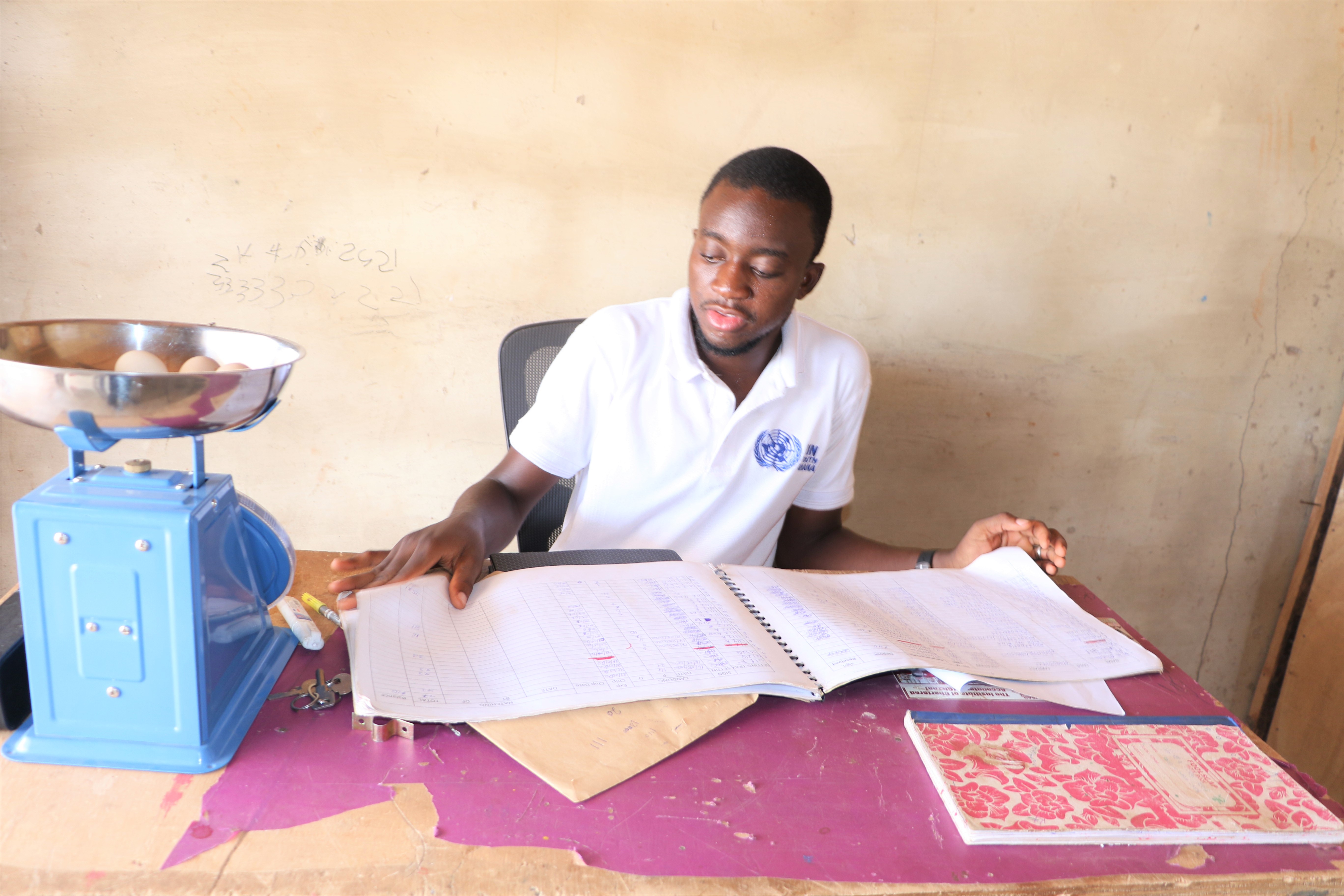

Iddrisu Alhassan working in his hatchery.

As a teenager, Iddrisu Alhassan Kobga, the only child with formal education among five siblings, was burdened with finding a solution to his father and other farmers’ age-old unproductive traditional ways of hatching guinea fowl eggs, until he succeeded in making incubators from scrap fridges at age 20 after senior high school.

“Guinea fowls are wild birds and will not sit on their eggs to hatch them after laying. So, we had to look for broody hens to add the guinea fowls’ eggs to theirs. The challenge was that, the number of eggs you could hatch was limited because the broody hen can only sit on a maximum of 20 eggs. Some of the guinea fowl eggs, we had to eat them and usually, most get spoilt”, Iddrisu Abdulai, father of Alhassan in Dungu Kukuo, Tamale in the Northern Region of Ghana narrated.

Iddrisu Abdulai, father of Alhassan.

With his burning desire to solve the hatching challenge, during his senior high school (SHS) vacations, young Alhassan would borrow smart phones from friends in his neighbourhood, to research on incubating and hatching guinea fowl eggs. This is because guinea fowl meat has become a delicacy and meat of choice for most people in Ghana, leading to increased demand. But the bulk of guinea fowls are raised by subsistence farmers mainly in Northern Ghana, who mostly use traditional methods to hatch eggs, resulting in low quantity and quality of keets.

Guinea fowls

The Breakthrough

“After completing SHS in 2017, I was eager to improve my local knowledge, so I continued to learn on YouTube and one day I saw someone in India using old fridges to incubate duck eggs. So, I decided to try the concept for guinea fowl eggs, with old fridges I went for from a friend who deals in scrap ”, Alhassan stated.

He needed money to purchase few tools to prototype his first incubator from the scrap fridge. So, Alhassan said he picked up a job from a car washing bay and in less than a year, he was able to save enough to purchase the needed tools such as thermometer, electric bulbs, heating coils, motor, a timer, and a humidifier.

“With my first trial with the incubator I made with the old fridge, all the eggs got boiled, because the heat was too much. I tried the second time and I got two eggs hatched out of 20. My dad asked me to stop because I was spoiling the eggs and he felt the electricity I was using was too dangerous, but I continued. The third trial, I was happy to have 20 eggs hatched out of 38 but later I realized the remaining eggs didn’t hatch because they were not fertile”, Alhassan noted.

Alhassan keeps improving the technology and started commercial hatchery services with his 200-capacity recycled fridge incubator, with few clients in 2018. Due to the high demand for his services, he wanted incubators with bigger capacities.

“In 2019, one of my friends showed me a Facebook advert from the United Nations Development Programme (UNDP) and the National Youth Authority, who wanted to support young innovators with grants to implement their innovative ideas. So, I applied and luckily, I won the USD5000 grant. This was my breakthrough”.

Alhassan was among the 16 young innovators enrolled in the Youth Innovation for Sustainable Development (YISD) Challenge, who also benefited from a business development, incubation and mentorship support from the Ashesi Design Lab.

A full-fledged hatchery and support services

“I used the UNDP money to build this production house, separated it into two, with a hatchery production unit and an office space. I also used some to register my company, Uptech Services, bought all the needed equipment including a back-up generator, welding machine, furnished the office and locally made a big incubator from a galvanized metal because I wanted a bigger capacity to meet the high demand. This gives me 3000 capacity, making it possible for me to serve over 100 clients now, who incubate their eggs at Ghc1 per egg”.

Alhassan in his hatchery production unit.

In addition, Alhassan trains farmers on how to cater for their guinea keets with organic feed and locally made vaccines. He also prepares and sells organic feed and builds incubators for farmers who want their own space, for a fee. In less than a year of his formalized business, Alhassan has built incubators for five clients, with his latest and biggest client in Accra.

“I usually use WhatsApp platforms and my company’s Facebook page to advertise my services, so recently I got a client in Accra and went to build a 8000- capacity setter and a 6000-capacity hatcher, at a total value of Ghc13,000 (about USD2,240). He is so far my biggest client and he is a poultry farmer”, he noted.

Alhassan showing his biggest contract.

Clients he built incubators for are making a living from the hatchery business.

“Alhassan built a 90-capacity incubator for me, from an old fridge at Ghc1000. I learnt from him and built a 150-capacity incubator myself. I use the 90-capacity incubator for commercial purposes, incubating eggs for other farmers at Ghc1 per egg. The 150-capacity incubator is for me. I buy 20 eggs for Ghc25, and they hatch between 25-28 days. I sell the day-old guinea keet at Ghc5 per one. Aside the commercial incubator, averagely I get about Gh500 a month from mine”, stated Fuseini Diyaa-Ul-Haqq Wun-Nam, a young poultry farmer and a client of Alhassan in Dungu, a suburb of Tamale, in the Northern Region of Ghana.

Fuseini with his two recycled fridge egg incubators.

Another client of Alhassan, Nlihiriba Saeed, a primary 5 teacher, who is now rearing poultry on a part-time basis, thanks to the 1700-capacity incubator Alhassan built for him.

Currently Alhassan is pursuing further studies at the Tamale Technical University. He employs two other staff at Uptech Services, a Welder, and an Office Manager. His greatest desire, he said, is to get more support to purchase a feed mixer to produce feed in larger quantity because the demand for feed is high due to the farmers’ ability to hatch more guinea keets. He also wants to have a standardized hatchery facility to serve more clients.

Alhassan has now realized the prospect of turning his father’s guinea fowl production challenge into a business opportunity. With the high demand for hatchery services, he has built an enterprise that addresses the challenges of guinea fowl egg hatching in his community, providing opportunities for himself, his family, and others.

Unemployment can be reduced if many more young people in Ghana, like Alhassan, are supported to unleash their potential to find solutions to societal challenges and create jobs for themselves and others.

Alhassan in a poultry house he put up for his father, so he can focus on ploughing back his profits into his business.

###

Footnote: Story & Photos by: Praise Nutakor and Sylvia Senu/UNDP Ghana

Locations

Locations